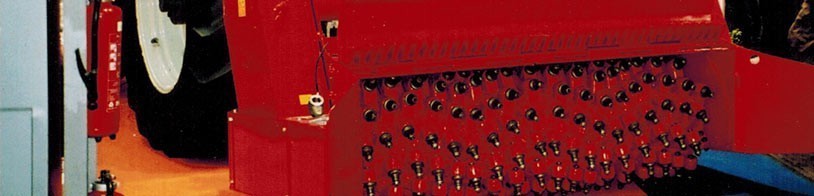

Disc ScreenerTM Disc Screening Bucket by Dromone

A Screening Bucket with all the functionality of a digging bucket in one easy-to-use excavator attachment. Increases the speed of on-site dig-screen-back fill operations leading to reduced material handling costs and logistics.

- Complete with high torque high speed hydraulic motors for optimal material processing

- Ramp in and ramp out hydraulic operation will increase the life of both excavator and Screener

- Extra interchangeable rotors available to cope with most challenging and varied material

- Robust and effective bucket design with high wear resistance

- All teeth compatible with the CAT tip and adapter system giving increased machine standardization and inventory cost savings

- Bi-directional rotor system reducing the build up of material and eliminating blockages

- A fully serviceable modular design enabling on site maintenance All consumable parts are replaceable on site increasing return on investment

- Central greasing points for fast and easy maintenance

- Rotor system safety guard for added protection

Sizes available to fit excavators ranging from 13 to 35 tonnes

Digging Capacities

10-13t screener - capacity of 0.5 m3

16-20t screener - capacity of 1 m3

30-35t screener - capacity of 3.7 m3

|

Freatures |

Customer Benefits |

|

A Digging bucket system |

Capable of digging virgin soil Increased efficiency & reduced bucket change |

|

Capacity ranges from 13T machines to 40T machines |

Increased Productivity 50T to 110T per hour |

|

Easy access to chains & sprockets |

Increased up time Lower maintenance cost |

|

Wide range of digging teeth |

Customer request, flexibility |

|

Screening Cleats fitment CAT 225 Std pin & retaining washer |

Standard parts, quick change cleat retaining system |

|

Powerful Dual Hydraulic Motors |

Better Screening action. Higher start up torque available |

|

Available via the DROMONE Quick Coupler System |

Increased up time Fits a range of excavators |

|

Central grease system |

One greasing point for all bearing housings |

|

Rear safety grill |

Additional bucket support & safety |

|

Vertical Rotor System |

No interference for digging applications Better material output using the bucket side wall openings |

|

Dual Rotor action |

Allows rapid rotor direction change if jamming occurs during Screening |

|

All wear surface constructed using WELDOX |

Strength & Durability. Increased Product Life |

|

Diamond Heavy Duty 140H Cottered chain |

Increased reliability, great power delivery |

|

Interchangeable Rotors |

Varied Screening application |

|

Reversible Cleats |

Increased Cleat life, longer Screening activity |

|

Banana Bars |

Digging application |

|

Self Contained Greasing System |

Six months automatic chain & gear lubrication |

|

Split Gear Drive |

Rapid Screening output |

|

Screening shell side windows |

Better output, Wider spread of screened material, better material aeration |

|

Inside wear racks |

Interchangeable, easily accessed, protects the Screener Shell |

|

Bearing housing complete |

Easily removed & accessed |

|

Side inspection windows |

Good access for bearing housing & greasing system inspection |

|

High Quality Bearings |

Durable & Long lasting |

|

Bearing Housing Seals |

Dual “Z” Seal system with additional rubber seals |

|

Bearing Grease |

Load 400, Calcium based, water repellent |

|

Bearing Greasing System, One grease point |

Serves all bearing housings |

|

Strong Robust Shell design |

Superior digging performance |

|

Dual Hydraulic Motors |

Better Power Train for better performance |

|

Adjusting Motor mount plates |

Motor, bearing chain adjustment |

|

Dual Cross Line Relief valves |

Instance Hydraulic relief response, dual flow. Fitted on both motors, face mounted |

|

I” Hydraulic Hose |

High performing flow & pressure delivery |

|

Hydraulic Motor Case drain |

Hydraulic Motor protection & lubrication |

|

Soft start hydraulic valve |

Preserves all Power Train components during Screening start up |

|

Hydraulic Hose Configuration |

Robust design & protected using plastic spiral wrap |

|

Hammer line Hydraulic supply |

Conventional Hydraulic connection |

System 1

General Purpose Rotor

Applications

- Medium Volume Sand Pit applications

- Recycling waste aggregates e.g. road building

- Separating building site aggregates from rock, stone or bricks

- Pipe Line installation

System 2

Gravel Screening with rock inclusions to 50%

Applications

- Application similar to System 1

- Capable of crushing small rock content in aggregate

- Separating building site aggregates from rock, stone or bricks

System 3

Fine screening <20mm output

Applications

- Golf Course and amenity preparation

- Land Reclamation

- Land Fill site soil management

- Soil Treatment applications in oil field applications

- Soil Treatment applications in Land Remediation applications

- Recycling

- Sand arena aeration

- Collieries wash processing

System 4

Double Cleat system

Applications

- Medium & High volume Sand Pit applications

- Recycling waste aggregates

- Aggregate separation

- Pipe Line installation

- Remediation & blending

© The St. George Company Ltd. | Toll Free 800-461-4299 | Phone 519-442-2046 | Fax 519-442-7191

TERMS & CONDITIONS

WARRANTY & DISCLAIMER

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12